Only two items are used at every step of the fly, and rather than spending precious dollars on tools that are simply more expensive because they can be, spend your money where it really counts, by upgrading your scissors or your vise.

The fly tier’s vise and one or more pairs of quality scissors will always justify their cost simply because they are constantly in use, their quality levels increase dramatically with the dollars spent, and their capabilities increase with the increased outlay, as blades and tips become finer and sharper, or jaws become capable of a wider range of hooks, can rotate, and can attain the same nosebleed price levels as lesser tools, so you don’t feel left out.

Fly tying vises being too expensive to own more than one or two of them, thereby making me blanch at the thought of buying several for review, but scissors are enjoying a renaissance in both price and quality, and a canny fly tier intent on upgrading his tool suite should learn where the good scissors grow, and how to determine what he really needs in light of this vast unexplored continent of expensive cutlery.

Scissors, and the Vastness of Options

All the best scissors grow in the medical and dental professions, and what’s available from fly shops are the cheapest quality scissors, mostly made in India or Pakistan. Both regular and dental surgery have created thousands of different types of specialized scissors that you cannot imagine exist, until you are curious enough to visit an online medical supply house, and dive into all the names, sizes, and shapes.

The myriad of choices, shapes, cutting edges, and materials are likely to be a bit daunting to your untrained eye, but I include enough information to help you limit your focus to a few important qualities and the types of tips, frames, and edges available to make your choice and your dollars go further.

Tips

For the fly tier the sharp fine tip is the most desirable element in a scissor. Medical scissors can have a tip fine enough to trim a single fiber from the inside of the eye of a hook, but that degree of metalurgy comes with a high price, both in dollars and in the education of the fly tier that spent the $600 necessary to own those scissors.

Medical scissors also come with blunt tips, rounded tips, curved, straight, and one rounded tip and one fine tip, but for most fly tying uses the dual fine tip is preferred. Fly tiers may lust after other types of scissors, once they learn of their existence, like Wire Cutting scissors would be superb for cutting heavy feather stems, wire, and bead chain. Medical supply houses often describe these as “heavy pattern” scissors, or heavier frames designed for increased force, and most come with one serrated and one straight edge designed specifically for cutting stainless steel wire.

Stainless steel wire is the preferred standard in dentistry and medical surgery due to its strength and possesses the highest intrinsic hygiene value, requiring less disinfecting chemicals to provide a sterile surface. Stainless steel wire would destroy most fly tying scissors very quickly, so the extra “beefiness” in frame of a heavy pattern scissor is welcome.

For most tiers the question of which tip will reduce itself to straight or semi-curved. Fly tying scissors are typically straight points, but scissors designed for fine work are often available in both straight and semi-curved. The curvature allows the cutting points and fingers of the user to not block the view of the area being worked on, giving greater visibility for precision cutting. Most tiers learn with straight points, many prefer the semi-curved once introduced to them solely due to the increased visibility garnered at the point of the cut.

Edges

The “Supercut” blade (typically with black handles) are superfine serrated blades. These serrations are much finer than anything available to fly tiers and will positively grab and hold anything ensuring no slippage during the cut. Tiers are familiar with hair or fibers slipping along the blade as it closes and we compensate without realizing it, often trimming two or three times to get a single even cut. Supercut scissors prevent any hair from slipping and you will get straight and even cuts on fibrous materials every time.

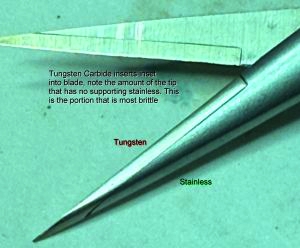

Tungsten Inserts are small insets of Tungsten Carbide imbedded in the leading edge of each blade. Tungsten is among the hardest of steel, so it makes a superior cutting edge. It is also the most brittle of steel, so you can destroy the points simply by dropping them onto a concrete floor. If you are not careful and cut toward the hook shank perhaps catching the tips on the hook shank, you can remove both tips in the blink of an eye, destroying the scissor in the process. Tungsten Carbide scissor usage requires the tier to relearn how to use scissors, and how to protect the points properly.

Most medical scissors are simply stainless steel which is a softer cutting edge and less prone to damage. Many medical scissors have “German Stainless” stamped or stenciled on them, which refers to the type of steel used versus the steel (or scissor) originating in Germany. Metalurgy analysis suggests sulpher and phosphorus are added to traditional stainless to make this variant, it is considered a “soft” steel.

Ceramic bladed scissors are a ceramic coating added to stainless or tungsten inserts to make the edges harder, sharper, and last longer than stainless or tungsten normally would. Ceramic coating also reduces glare on the scissor, and makes it resist corrosion better. Ceramic coated scissors are incredibly expensive, lusted after by every fly tier that handles a pair, and should be considered only if you have a friend whose a surgeon, a rich uncle, or win the lottery. Ceramic OR (operating room) grade scissors typically range between $250 to $600, depending on size and type.

… and yes, the gold coating on their handles is real gold.

What a Hammy Handed Meathead needs to know before buying the Good Stuff

Medical scissors are available in four grades. There’s the disposable scissors from Pakistan and India that are $10 or less, and make up most of the offering from fly tying shops, and are available by the squillions on Ebay at much cheaper prices. A decade ago these were really poor quality, but the sample purchases made recently suggest vast improvement on both fit and tolerances.

As these scissors are less than ten bucks each, you can order a sample pair to check the points and quality of blade construction before ordering more. These are great scissors for equipping a club fly tying class – or used as loaners for same. These scissors mimic the fancy scissors by using gold colored handles, and stencil “German Stainless” on the frame, hoping you’ll think the scissor is made in Germany.

Often these scissors are labelled with the term “TC” for Tungsten Carbide, but none of the samples that I bought had tungsten carbide inserts in the blades (see the below picture), so this is simply a sales tactic hoping to dupe the unwary.

There is the high quality disposable from both US and German vendors, and are usually in the $17 to $25 range. These scissors are typically better than our fly tying scissors, have fine points, are made in the US or Germany, and are typically only made of stainless steel.

The third grade of scissor is the “supercut” and tungsten carbide scissors. These scissors can range from about $75 to $250, and are better than anything offered by fly tying vendors. The above picture (at left) shows the fit of the blades on a pair of semicurved Tungsten IRIS scissors. Note that daylight cannot be seen between the two blades from their tips all the way to the screw fastener. This is the hallmark of the best scissors as they only cut where the upper and lower blades meet. Daylight means little or no cutting ability on that segment of the scissor.

The ultimate grade is the ceramic coated scissor, and is largely out of the tier’s budget. Paying $300 to $600 for a pair of scissors that you are certain to destroy should they be your first set of quality scissors, is for trust fund babies who can afford thousand dollar fly rods, and $200 nippers. I recommend learning to use tungsten carbide scissors first before moving higher on the food chain, and prior to ceramic coated you should have destroyed at least one pair of tungsten scissors learning how to use them properly.

These scissors (tungsten and ceramic) should be approached warily, as the fly tier needs to learn how to use scissors of this quality, given that flesh and ligaments can be soft in the comparison to some of the things you may be cutting with your inexpensive fly tying scissors.

Learning how “soft” steel can be

Stainless is considered a “soft” steel, and using a quality scissor improperly will show you how soft stainless can be.The screw joining the frame and blades is a much harder steel than the stainless of the scissor, so the more pressure applied to the legs of the scissor to make the cut, the more the screw will deform the soft stainless housing that surrounds it. Over time this screw hole deformity becomes “slop” in the meshing of the blades, and the legs of the scissor will show increased play in all directions. Eventually the scissor will be destroyed, or the screw can deform the screwhole to the point where the scissor no longer functions as such.

Test your existing fly tying scissors for damage in the same fashion. Simply grip each fingerhole and move the legs in opposite directions vertically. The distance the legs move away from one another in the vertical plane shows how much deformity or slop is present in the screw hole.

Your first set of really excellent scissors will be your ritual sacrifice, you will destroy them learning what you can and cannot do. Destroying good scissors should take years if you don’t do anything stupid, so be mindful of their use and assume you will destroy them via time-honored trial and error.

Rule 1: Heavy cutting needs to be done with heavy duty scissors . I have a “heavy pattern” scissor with standard stainless blades that I use to cut wires, monofilaments. stems of peacock and other thick flight feathers, and bead chain. These heavier scissors have lasted about 30 years of commercial tying with no obvious damage, due to my choosing the proper tool for this job. I may succumb to a set of inexpensive wire cutting scissors just to try them in a similar role.

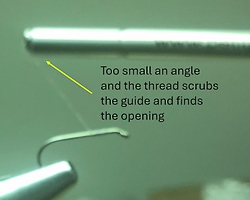

Rule 2: Stop cutting toward the hook shank with tungsten carbide scissors, learn to cut “away” from the hook shank instead. Closing the tips on a hook shank will remove those fine points you paid so much for – so learn how to minimize risk. Use Needle Scabbards on your best scissors to protect them when not in use.

Rule 3: Fine pointed medical scissors are designed to cut flesh, skin and soft organ tissue. They are not used to cut heavy tendon and bone. This learning curve is identical to a surgeon-in-training, you have to learn which tool is best suited for what type of cut. Use your heavy scissors to cut leather for mouse tails, brass or stainless wire, or anything else rigid or thick.

Of the thousands of medical scissors, what should I be looking for?

I have linked to numerous different medical supply houses in this article so you can see the hundreds of types of scissors available. There are also plenty of explanations for the basic types of medical scissors and their uses available on the Internet.

A fly tier who is ready to make the leap from fly shop to doctor’s office should focus on these attributes.

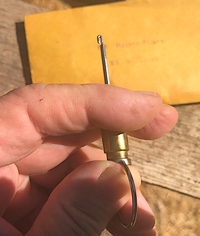

IRIS Scissor : Iris scissors have small, fine tips and sharp blades. They were originally designed for ophthalmic procedures but are now used in a wide range of applications like delicate tissue dissection, cutting fine sutures, or removing delicate ocular tissues. Note the medical uses all mention delicate or fine, pay attention. IRIS scissors are best suited for the fine work needed on flies. Stick with this style in your initial foray, and get more emboldened once you’re used to the types and styles.

If you want to look at a new type of scissor, order the seven dollar version of it from a medical supply or EBay. Test the heft, length, blade, and cut, using the inexpensive version. If warranted, you can buy a better grade of the scissor once you’re comfortable with its attributes, capabilities, and shape.

Length: 4.5″. Scissors come in many sizes, for fly tying … stick with the 4.0 – 4.5″ lengths, depending on your hand size. I prefer the 4.5″ length, it’s typically the standard length for most fly tying scissors sold in fly shops as well. (4.5″ is 11.4 centimeters, Germany is on the metric system. and many supply houses list their metric size.)

Large fingerhole. Scissors are available in different fingerhole types, ribbon and standard. Medical scissors are designed for male fingers so all should have large enough fingerholes, but given a choice, opt for more room.

Fly tying scissors all have straight tips, medical scissors offer semicurved, slanted, straight, and scissors whose blades are tilted 45 degrees. Start with straight points and work your way up to the semi-curved once you’re more comfortable. Semi-curved scissors are designed to remove scissor and fingers from the same plane as the cut being made – meaning you have increased visibility of the work area so you have better control over the single hair you’re removing from the eye of the hook. I prefer semi-curved, but I use both styles.

There are many high quality makers of medical scissors and most reside in the US or Germany. I cannot vouch for all, but if you are concerned and wish to make a large dollar purchase, I recommend the Miltex brand, Miltex being a German made scissor. I have also purchased numerous Hu-Friedy scissors, and I can recommend those as well.

I have used Miltex scissors for at least 40 years and have never had a bad pair. I have destroyed a couple pair, but this was the normal process of learning about the scissors and their limitations. That first sacrificial pair paid for itself many times over as I did not repeat the same mistakes with others I have purchased.

… and Lastly.

If you’re contemplating a purchase please recheck the scissors length, and tip type before buying online. You may even want to call them if the photographs are grainy or too small. It is easy to mix a round tip for a fine tip or a blunt scissor, if you’re not playing close attention.

Some states require the purchaser of the medical scissor to be a doctor, and in those states a license or license number must be produced at the time of sale. Don’t buy from the supply houses that are limited by this requirement. All the eBay scissors and 90 percent of the remaining supply houses do not have a license requirement, so simply shop a different state.

As only the largest of cities host stores selling these items, ask your dentist or dental surgeon to look at his tools. Most dentists are boring conversationists, due to all their conversations being one sided, you being hampered by a mouthful of stainless steel and someone else’s fingers, so have him show you some of the scissors he has at his practice, or … tell you about the merits of the different vendors he’s used .. or where he purchases his tools.

… and when the SOB isn’t looking you can pocket a handful of the Good Stuff ….