I just can’t seem to leave well enough alone. Dogged determinism has me squinting at the screen digesting numbers and errata when I should be mowing lawn or squinting at a small fly going in harm’s way.

I just can’t seem to leave well enough alone. Dogged determinism has me squinting at the screen digesting numbers and errata when I should be mowing lawn or squinting at a small fly going in harm’s way.

Like the evolution of medicine, fly line manufacturers are no longer content with a general practitioner, they’ve pushed us down the specialization path with glee – leaving us to ponder whether Mango is better than Avocado, slick is superior to textured, and whether a line called Salmon is needed for Salmon, or just another gimmick to add to the already horrendous weight of our vest.

Much is made of all the differences, with anglers professing allegiance to one camp or another, or merely shivering in the middle; unsure and undecided whether the voices of vendors and vendor-backed media are taking them down the primrose path.

Our angling publications aren’t much help, authors vie to give manufacturers the least offense, hoping the flow of freebies continue unabated. Product reviews always contain superlatives, the marketing materials contain even more – and end prematurely with little more than, “it’s cool, definitely slick despite the ridged and bubbled finish and the Puce polka dots allow you to maintain contact despite blending with bankside shrubbery.”

Vendors are in constant competition, and pricing depends on mass production, each manufacturer wants as few pots of bubbling plastic polymer as possible. Cortland and Scientific anglers prefer PVC, Airflo likes Polyurethane, and everyone touts their mixture as the “one true God.”

But with the plethora of specialty lines and the maker’s desire to ensure you own all of them, they’ve trapped themselves. The AFTMA standard requires the line adhere to a given grain weight in its first 30 feet. Like NASCAR, everyone has a similar rule set – and there’s only so much you can do to a fly line taper. Shorten, lengthen, make “stairsteps” of increasing or decreasing line size, but when you’re done it’d better weigh within a fixed range just like your competitor.

We’ll assume everything they say about coatings, compounds, and textures is true, allowing us to get past the nouns and acronyms, past the religious fervor of Sharkskin, SYLK, and softeners, and focus on the product’s taper. We may not be able to discern the difference between hydrophobic and hydroponic, but we’re expert in soft butts, big bellies, and a long tip when cast.

That “feel” comes from the taper – and whether it’s a sinking line imbued with Tungsten dust or a floating line with microbubbles, we’ve flung them with great passion for years; we know what we like, and might be able to answer, “are all these specialty lines really necessary?”

Remember, “as few pots of bubbling plastic as necessary” – and regardless of the spittle and vitriol, it’s likely all these lines use the same basic formula of plasticizers and polymers.

Method

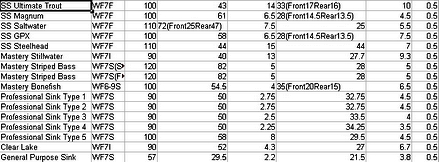

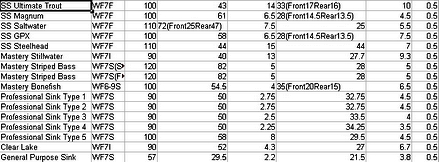

I chose a AFTMA WF7 F/I/S to show the taper of each vendor fly line. These numbers are taken from the vendors website and/or discrete PDF’s constructed by the vendor which contain their line specifications.

We’ve ignored sink tips intentionally as their taper is compounded by the sinking portion.

Length = Total length of the fly line (feet)

Running Line = Length of the level running line portion (feet)

Rear Taper = The length of the rear taper of the head (feet)

Belly = The length of the fly line belly (feet)

Front Taper = Length of the front taper (feet)

Tip = the length of the level tip (feet)

If the line has a compound taper in the belly portion that taper is denoted by its overall length, and the steps of the taper in parenthesis. 35(Front20Rear15) is 35 foot overall belly length, the front 20′ is different from the rear 15′.

Lastly, I took every WF7 the vendor sold and compared their respective tapers in a chart, allowing you to see real differences in the line taper without being swayed by box art and advertising.

Scientific Anglers

I’d describe Scientific Anglers as the most prolific of the fly line kingdom. It’s apparent that almost every discrete line they manufacture has some small difference. These differences are not drastic and begs the question, “can the average angler detect the taper, and will it make much difference in his casting?”

Example: Take the Lefty Kreh Signature and the SA Professional floating line. The differences between the two are a 2.4 feet longer rear taper on the Kreh line, and the Professional floater is the converse of the above, a 2.4 foot longer head taken from the rear taper. Both are the same price at Cabela’s.

All other line specifications are identical, suggesting the Kreh and Professional are largely the same. Manufacturers would claim the Kreh gives the softer presentation due to its longer tip – you’ll note in the marketing material below taken from the 3M and Cabela’s websites – no mention is made for the longer tip – it’s not considered an asset.

The marketing at Cabela’s is very different, differentiating the two, and there’s no mention that the Professional series contains the Lefty Kreh Signature line, as demonstrated by the Scientific Anglers website. That’s not an indictment so much as demonstrates the pains by which advertising attempts to make them all quite different.

Lefty Kreh:

It’s specially engineered by Scientific Anglers to possess optimal density for high-flotation applications. Both supple and easy to use, this line has a versatile midlength head that makes it suitable for a wide range of fishing situations. Special 3M lubricants increase the slickness of the Signature Series, resulting in superior casting performance.

Professional:

Scientific Angler’s new Professional Series Floating Line has optimal density for high flotation, and is supple for ease of use. With a braided multifilament core, internal lubricants to increase slickness and enhance shootability, and integrated UV inhibitors, this line is ideal for a wide range of conditions.

The Scientific Anglers website is terse in its prose, listing an abbreviated preamble and bullet points to describe each line’s attributes.

Lefty Kreh Signature

Applications:

- Excellent general-purpose line

- Easy to cast and high floating

- Optimal line density for high floatation

- Supple and easy to use in most conditions

WF taper characteristics:

- Versatile mid-length head designed with input from the master himself – Lefty Kreh

Core:

- Braided multifilament nylon

Coating:

- 3M PVC formulated with special internal lubricants to increase slickness and enhance shootability

- Integrated UV inhibitors for increased durability

Professional Series Floating

Applications:

- Excellent general-purpose line for all weather

- Optimal line density for high floatation

- Supple for ease of use in all conditions

WF Taper Characteristics:

- Group-tailored heads for general use

Core:

- Braided multifilament nylon

Coating:

- 3M PVC formulated with special internal lubricants to increase slickness and enhance shootability

- Integrated UV inhibitors for increased durability

We find both have the UV Inhibitors, both have the same superlatives in describing function and use, the only difference being that the Lefty Kreh line is “designed by the Master himself” and “easy to use.”

I’d suggest that the lines are identical (except for the 2.4 foot reallocation) and that a casual angler isn’t looking at two different lines – but is in fact looking at pretty much the same line.

So why would a vendor go to the trouble of building a feature into the line that was singular when compared to other tapers, yet make no mention of it? It’s likely they’ve used the superlative already in a half dozen other lines, and it’s important to distinguish each line as an asset to the angler’s overall quiver.

So you feel you need them all.

Note that the SA Mastery Stillwater has the 2nd longest front taper of any fly line they make, but it’s length isn’t mentioned in the marketing material. Ditto for the Supra Floater, it’s the third longest forward taper SA makes – yet no mention of that attribute on their website.

The Mastery Bonefish and Sharkskin Ultimate Trout Taper both advocate their long tips to provide graceful presentation, and there’s no sense confusing you as to how many “long tip” fly lines you really need, is there?

Both the Mastery series and Sharkskin lines are more expensive than the Professional and Supra series – why not save the best superlatives for your high end lines? That’s good marketing.

Scanning the chart of the Scientific Angler lines above, many more similarities announce themselves, like the Saltwater Specialty, and the Specialty Bonefish line – a mere two foot difference in taper location akin to the Lefty / Professional.

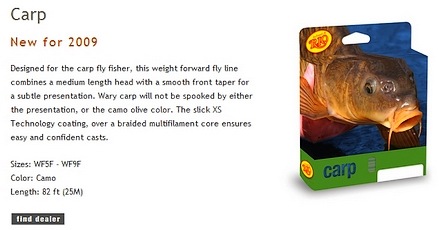

There are many pronounced differences in the tapers as well, what the angler needs to ask themselves is outside of the marketing hype of slickness, texture, color, plasticizers, and coatings – is there much difference between my choices for a Carp line – and would the Bonefish taper be just as good?

Most anglers won’t be able to discern the difference between 2 foot of taper shoved forward, and as we’re ignoring all else other than their functional spec, it appears much of the cornucopia of fly lines tapers are not as distinct as we’ve been led to believe.

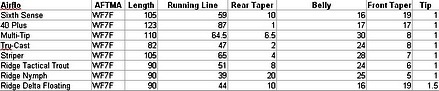

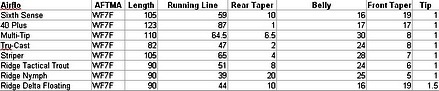

Airflo

Airflo has a much smaller stable of fly lines than Scientific Angler, and like SA they’re showing the same advertising tendencies. Both Airflo and Cortland include a full foot of level taper at the tip, unlike RIO and SA which opted for 6″.

Airflo has a much smaller stable of fly lines than Scientific Angler, and like SA they’re showing the same advertising tendencies. Both Airflo and Cortland include a full foot of level taper at the tip, unlike RIO and SA which opted for 6″.

The Delta, Sixth Sense, and 40 Plus all have long front tapers to ease the splash of presentation, and the balance of the Airflo suite are roughly similar with the weight shifted forward or backward by less than 5 feet.

Despite the differences between the two basic groupings of Airflo lines, only the Delta advertising mentions the long tip. The Sixth Sense and 40 Plus make no reference to the tip at all.

(The 1.5′ tip on the Ridge Delta Floating appears to be a website typo)

We should be asking ourselves when the manufacturer touts his “extra long belly” as an aid to long casts, long as compared to what? There’s no such thing as a normal belly, tip, or rear taper, ensuring every possible change to the line can be touted as a benefit.

“With the debut of the Singlebarbed line and it’s Zero-Taper tip, the sumbitch lands like a gutshot mallard – offering the angler the advantage of visual feedback on the location of his fly. Available in Raspberry Red, Lemon Yellow, and Orange Orange..”

Whether it really makes a difference in your casting, you’ll have to try one and find out.

I fear there’s plenty of lip gloss in fly line advertising, largely to differentiate similar products – giving us anglers the illusion we need multiple lines.

Wednesday, Part 2 of the series, “Are they Rogues or Demons, and why didn’t they tell me snipping 3 ” off the tip of a RIO Striped Bass line yields a RIO Clouser and $9 savings?

Cortland appears to have made a concious decision to simplify everything but the box art. It’s as if their strategy is, “We’ll make a taper that we like and use it on everything, if you like the feel of how a Cortland casts, then you’ll like all our lines.”

Cortland appears to have made a concious decision to simplify everything but the box art. It’s as if their strategy is, “We’ll make a taper that we like and use it on everything, if you like the feel of how a Cortland casts, then you’ll like all our lines.” I just can’t seem to leave well enough alone. Dogged determinism has me squinting at the screen digesting numbers and errata when I should be mowing lawn or squinting at a small fly going in harm’s way.

I just can’t seem to leave well enough alone. Dogged determinism has me squinting at the screen digesting numbers and errata when I should be mowing lawn or squinting at a small fly going in harm’s way.

Airflo has a much smaller stable of fly lines than Scientific Angler, and like SA they’re showing the same advertising tendencies. Both Airflo and Cortland include a full foot of level taper at the tip, unlike RIO and SA which opted for 6″.

Airflo has a much smaller stable of fly lines than Scientific Angler, and like SA they’re showing the same advertising tendencies. Both Airflo and Cortland include a full foot of level taper at the tip, unlike RIO and SA which opted for 6″.

You too can enjoy the official vineyard of the Federation of Fly Fishermen.

You too can enjoy the official vineyard of the Federation of Fly Fishermen. While the rest of you debate whether it adheres to the spirit of things I’ll be quietly mixing it into my head cement. I’m preprogrammed to break ranks with the crowd at the first opportunity, exploit fish horribly, then asks forgiveness in a cataclysm of guilt.

While the rest of you debate whether it adheres to the spirit of things I’ll be quietly mixing it into my head cement. I’m preprogrammed to break ranks with the crowd at the first opportunity, exploit fish horribly, then asks forgiveness in a cataclysm of guilt.

It might be the perfect campsite companion, she cuts off your air supply wrapping the GPS waterproof cell phone around your neck, and can reel you in when dinner’s ready.

It might be the perfect campsite companion, she cuts off your air supply wrapping the GPS waterproof cell phone around your neck, and can reel you in when dinner’s ready. Not to be outdone by the Retro Movement, the venerable Hardy and Grey’s dips its toe in the fiberglass market along with Sage.

Not to be outdone by the Retro Movement, the venerable Hardy and Grey’s dips its toe in the fiberglass market along with Sage.