Frank Matarelli was a towering, unsmiling fellow, partial to checkered hunting jackets. His physical stature and opinions brooked little disagreement, as he reduced the complex to simple, making current events, politics, and Grizzly hackle, all manageable in a single breath.

He lived out in the Avenues of San Francisco, on Irving Street, neighbor to his close friend Cal Bird. Both were prolific tiers, but Frank was the more secretive of the two, as only family and Cal were allowed to see his garage work area, housing his machinery and tool production. Cal described Frank’s tool building process as a wide leather belt, or harness, that allowed him to bend wire and steel via body weight. “Frank threw his body all over to bend wire to make whip finishers.”

Frank and I were both members of the Golden Gate Angling and Casting Club, and as I taught their fly tying classes for many years, we crossed paths frequently. While Cal fished closer to home, Frank took yearly vacations to Montana, and eventually purchased a vacation home there, close to his favorite fishing.

Frank was a machinist for the San Francisco Chronicle newpaper when I knew him, so his skills with metalurgy were acquired over a lifetime of machine shop work. I’m unsure what he was responsible for at the newspaper, but with all the heavy machinery on the premises, it’s likely both repair and fabrication were involved. He was a meticulous craftsman, as evidenced by the quality of his tools, and was always eager to invent the better mousetrap. He was a vocal critic of his competitors, but criticism was warranted given how poorly their tools performed, in the comparison, and how cheaply most were made.

One glimpse at Frank’s fingers and you understood why his whip finisher was so important to him. He had a job-related ridge of callous on the edge of both forefingers that prevented him from performing whip finishes with his hands. He often absent mindedly trimmed away this callous with nail clippers while talking with you, but the resulting uneven surface would sever thread instantly. His whip finisher kept the thread at a safe distance from his digits and ensured a successful knot.

Despite an imposing presence and his stark opinions, Frank was a grand fellow worthy of regard. He enjoyed watching other tiers weave their magic, and took pride in his ability to increase their skill via the quality of his tools. He always carried extra sets in his pocket at shows and many were his highly prized “presentation” tools, made with stainless steel instead of brass, that you couldn’t purchase retail, you could only get from Frank as a gift.

… and he gave away plenty of them. Frank would watch any tier closely and was keen to reward talent with a set of his tools. Just as keen would he lambast you for using someone else’s tool if you had a set of his already in possession. Both rewarding talent and his removing “inferior” products would always be done in good taste, with humor, as Frank was a real gentleman despite his gruff exterior.

Frank had multiple prototypes of tools made from a variety of materials. He made bobbins from both metal and wood, used brass, copper, and stainless elements in his tools, and even made hackle pliers, which he never marketed, but you could receive as a presentation gift. He made a lot more tools than most realize, given his wooden versions, his midge, regular, and long tube, bobbins, his presentation whip finishers, in regular and extended reach configurations, and the normal whip finishing tool. In addition to these, Frank made both a midge and regular size bobbin threader, and multiple bodkins, which also were only available as a presentation tool

When Cal Bird introduced his pair of dubbing tools, he mentioned to me that Frank was producing them for him in his garage. Cal was a caligrapher by trade, and produced all the instruction sheets and package labels for his tools, but Frank did all the wire work and shaping for Cal.

My proximity to Frank’s watchful eye meant I was a frequent beneficiary of prototypes and oddities, as well as admonishments when he found me fiddling with some new vendor’s offering. While I loved tinkering with new tools, I learned to pocket them if Frank’s shadow darkened the doorway. Frank knew I was a commercial fly tier as well as a casual hobbyist, and I was gifted numerous prototypes with which to fiddle. Frank knew that commercial tiers have different insights into products; how they wear on fingers, how easily they’re gripped, and how they are slid off the work surface versus held in hand. Quite a few club members were pressed into service to refine things as were numerous tiers in Montana, where he spent his summers.

I recently espied quite a few mentions of Matarelli tools on Internet forums, many inquiring as to their value as they are no longer made. Like most tiers, I’d not thought of “value” regarding tools, as efficiency of use will trump monetary value in every case. Recently I’ve thought I might explore some of the pricier bobbins to see if there is a fit replacement to the Matarelli long tube, and whether several decades, several flops of engineering alloys, and a couple additional sawbucks have increased the capabilities of Frank’s design, instead of merely their cost.

I have added some photographs of all of the Matarelli tools and prototypes in my possession, which will allow the WayBack Machine to catalog them for future generations. It’s important that those of us with first hand knowledge of these “OG” angling legends recount what they know so that future generations of anglers can learn as we did.

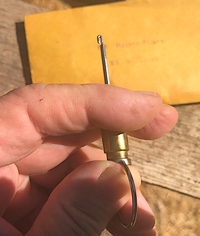

On the featured photo at the top of the article are the Matarelli Hackle Pliers, they were spring loaded where upward pressure of your thumb would extend a small stainless hook outwards to grip the hackle and lodge it against the barrel of the plier when tension is released,

All flavors of the presentation whip finisher; standard, extended reach, and wood handled, had a small “V” notch cut in the end of the tool to sever thread. The non-wood presentation model feature a silver, stainless steel barrel (handle) versus the brass of the traditional retail tool. This thread cutting capability makes them highly prized by those fortunate enough to own a pair, as the tool is already in hand when the finishing knot is applied, and the thread can be cut without reaching onto the work surface for another tool or scissors.

The walnut bobbin is for the “midge” size sewing machine thread spools. This is because all the old school tiers purchased thread in cones instead of spools, and decanted the thread onto sewing machine spools via a power drill held in a vise. Threads used for fly tying were much larger than today, and traditional sized spools were shallow and held much less thread than the thin, deep, metal spools for sewing machine use.

I’m sure Frank would be pleased to read many of the comments on the “value” topic of Matarelli tools, and how despite their increase in worth, not a single tier mentioned his willingness to part with his Matarelli tools at any price.