Spring is synonymous with the “Great Flush” wherein increased water levels caused by rain and snowmelt sends leaves, branches, empty water bottles, discarded Pandemic masks, and everything not nailed down – into whatever body of water is downstream.

I always seem to run into dirty water regardless of where I’m fishing and am always fiddling with flies attempting to find a solution to their visual appeal being obscured by debris and dirt.

The drought has complicated matters as well. As the water in lakes are drawn down it exposes loose dirt with little vegetation to hold it in place. Wave action caused by wind will stir that mix into a coffee colored slick that will extend it’s plume into the lake from the windward side of every point.

Wind and shallow water are common to both freshwater lakes and the California Delta. Vegetation tends to cleanse dirty water but a drought, coupled with the time of year, weeds are not available. Much of the underwater vegetation dies back during the Fall and Winter months, and the spring flush often empties into lakes whose weeds have not yet started their new cycle. The California Delta has less water level fluctuation and much more resident vegetation but is prone to wind which stirs the water in the shallows – disturbing bottom debris and sediment which quickly discolors water in the surrounding flats.

As fly fishing lacks many of the sensory elements of other types of fishing, like scent or sound, we are at a disadvantage when water conditions are less than ideal. Watching those Pro Bass shows often tempts me into using “Scent of a Thousand Nightcrawlers,” but I’ve resisted thus far only because the oily mess is likely to mat all materials and render flies lifeless and stiff.

Sound is a viable option on flies, but their method of attachment is a bit problematic. Many kinds of rattles exist for the bass jig market and might be adapted to flies with a bit of ingenuity.

The volume of rattle equipped baits on the lure and plug market suggests both lure manufacturers and anglers believe it attractive to predatory fish. As I’ve not read all the science (yet), I’ll assume the mob is onto something and all those rattle equipped lures are something more than a means to separate a fool and his money … and sound is an attribute to a fly in discolored water.

While not expert on sounds emitted by baitfish – it’s likely digestive noises and excess air are present in the innards of anything that isn’t a plant. Water transmits sound readily but I’m unsure whether “bad” noises exist and whether gastric noises or baitfish flatulence is attractive to predators. The act of swimming, either leisurely or frantically, is likely to add vibration (sound) into the water as well. The receptor on a predacious fish is likely its lateral line – as sound is likely transmitted through water as a vibration.

The bigger question is, which sounds and what pitch are triggers for large fish? Big sound, loud or soft, continuous sound or discrete notes?

I’d guess that the species and feeding behavior of the predator adds a unique mix of triggers, and Sailfish may respond to bigger sounds that would send a trout fleeing in terror. Schooling bait likely “sounds” different than a solitary minnow, so part of the mix will vary with the fish sought or imitated by the rattle equipped fly.

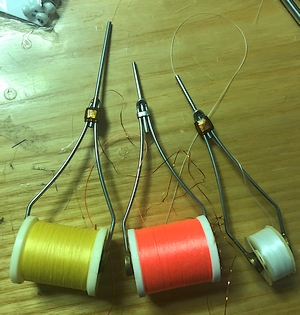

Rattles exist in a number of options, most are for jigs and bait casting gear. Three basic styles are the dual harness type (XTech), the “Pepper Jig” type – whose rattles fit into a rubber harness akin to a set of Mickey Mouse ears (rattles in the box), and the fly tying rattle (Eye Glass Rattle) – which are shaped like a traditional “barbell” eye, and attached in the same way.

All of these are “dogs with fleas” for the adventurous fly tier. Both the dual harness and the Pepper Jig rattles rely on a rubber element that can be lashed onto a hook with ease. Unfortunately, rubber will oxidize and you might lose the rattle after a season or two. The basic cylinder of the “Pepper” shaped rattle is problematic and bulbous, so securing it to the shank without using the harness is an issue, both in secure attachment and in its interference in tying the actual fly itself.

The “barbell” style rattle eyes have little or no sound as the beads are so tiny, so if it’s the noise you’re after, the fly tying version are essentially worthless. As I am unsure which sounds are most desirable to Striped Bass and Largemouth/Smallmouth, and sound is the solution to combat discolored water, I choose to use the larger beads and noisiest rattles ; the double barbell and/or Pepper Jig flavor.

The physics of rattles has to be considered as well. Rattles create sound as one or more “BB’s” hit either end of a air filled chamber. Air is buoyant so the larger rattles (containing bigger beads and more trapped air) can alter the buoyancy of the completed fly. Using a double rattle will exacerbate the issue, so it’s prudent to drop your flies in a glass of water to determine whether you’ve affected the rake or pitch of the fly in the water.

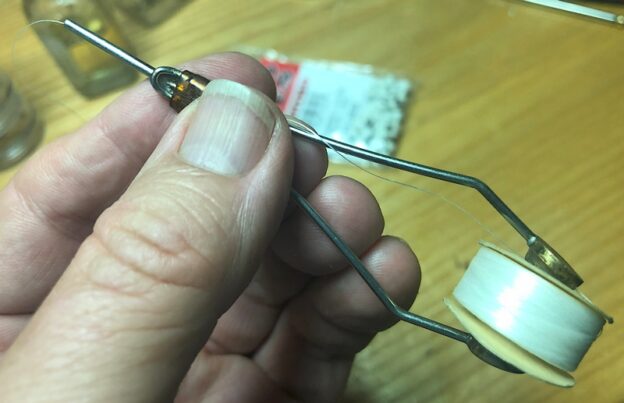

I chose to use a single rattle from the dual harness. I trim the harness at the center bulb and tie the stem portion onto the hook shank in the tail position. this allows the bucktail or marabou to flow around the rattle body and hide it within the fly.

It’s worthy to note that both the dual harness and “Pepper Jig” variants can be threaded onto the fly by simply forcing the hole in the center harness over the fly head or onto the leader itself. This offers the ability to add and remove rattles to your existing flies but relies on the elasticity of the plastic to remain securely attached. It’s plain the maker would have chosen a plastic that resists oxidation, as jigs are subject to sunlight as well as flies, but the force of casting the fly coupled with stretching the rubber ring over the hook eye will likely cause it to fail sooner than its traditional use.

On the above “Little Bluegill” you can see the single barrel of the rattle tied in at the tail position. I have spread open the marabou to show the rattle, and when fished the rattle is not visible nor does it seem to affect the fly action. Any buoyancy issues will be overpowered by the lead eyes up front.

Mounting the rattle at the tail keeps it from obstructing the gape of the hook. Threading rattles onto the leader or eye means the barrels have the ability to dangle below the fly and may cause some issues with hook setting on smaller hooks. I trimmed the tether short to keep the barrel up tight to the shank of the hook rather than allowing it to sag to one side or the other.

Marabou striper flies fully loaded with water are already heavy things to hurl, so I didn’t notice issues with the increased weight. A fully loaded 2/0 is about as aerodynamic as a small school bus, so wear protective gear regardless.

I fished Sherman Island just after two days of blustery wind last week and managed to score a single eight pound striper. The water was noticeably dirty from all the wind activity and while I cannot say it was the rattle that seduced the slimy SOB, I’d like to think I outwitted him on his own turf ..

More testing is required to prove anything however. I am scouring the Internet to see if there is any scientific work on the subject, that can translated from Latin into English, as I am interested on how pitch and tone might attract or repel – and whether I can manufacture something suitable to confirm any theories on this subject.

In the meantime, enjoy fiddling with these options most are available from any shops catering to lure and jig making.

I plan on using the same flies for Largemouth to see if they aid in catching fish on the muddy plumes of water that come off the points in the afternoon. Wind traditionally makes an appearance in early afternoon, and my wandering about on the bank has revealed that schools of Threadfin Shad use these plumes as cover from predators, foraging with relative impunity .. Dragging my fly out of such a plume might trigger something to dine, and I do so love to share my flies with things smaller than me…

I was shocked by the violence of the outburst. How us “fly fishing guys were NUTS”, and how the speaker – a largemouth Bass devotee – would rather submit to a colonoscopy before EVER learning to fly fish.

I was shocked by the violence of the outburst. How us “fly fishing guys were NUTS”, and how the speaker – a largemouth Bass devotee – would rather submit to a colonoscopy before EVER learning to fly fish.